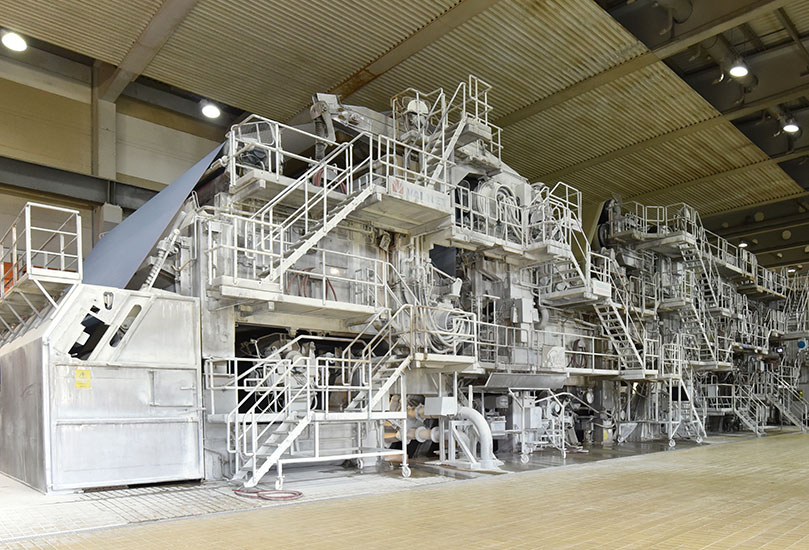

Paper machines

A lubrication system has the purpose of providing the machine with clean, conditioned oil for lubrication of bearings and gearboxes. Lubrication occurs through low-pressure spraying via calibrated nozzles. In paper machines, in addition to being a lubricant, the oil is used under high pressure, to provide hydrostatic or hydrodynamic lift on cylinder loading.

Benefits

- Robust

- Reliable

- Easy to use and maintain

- Advanced technology

- Precision and control of all movements

- Proportional control with analogue system

- Actuated process valves

- Solutions to meet specific customer requirements

Products

- Tools for pressure and temperature and flow control

- Proportional valves with feedback for controlling heat-exchanger coolant

- Dimensioning of piping for low ΔP

- Dimensioning of plate heat exchangers

- Dimensioning of duplex filters with low ΔP

- Hydraulic manifolds

- Low-pressure pumps for lubrication (vane pumps/screw pumps)

- High-pressure pumps for lift (vane pumps/piston pumps)

- Proportional valves

Systems

For more information, just get in touch ![]()

en

en  it

it