In a world seeking sustainable solutions, we are committed to doing our part. Beyond cutting-edge products, we are embracing Daikin's Environmental Vision 2050, an ambitious journey towards zero CO2 emissions and a healthier world.

Discover how our solutions actively contribute to this goal by integrating energy-saving technologies to reduce emissions and consumption.

DAIKIN Industries publishes an annual sustainability report. Read it HERE.

Our commitment extends beyond products; it's a holistic approach to sustainability, shaped by the understanding that every step counts.

Daikin Environmental Vision 2050

We will provide safe, healthy air environments while striving to reduce our CO2 emissions to zero.

Creation of products and services with high environmental performance

- Promotion of energy efficiency through inverters and other technologies.

- Adoption of HFC-32 and other refrigerants with low global warming potential, development of next-generation refrigerants, and promotion of heat pump technology.

- Reduction of environmental impact of materials throughout the entire life cycle, from supply to disposal and recycling.

Daikin Environmental Vision 2050

Daikin AIMS TO ZERO OUT CO2 EMISSIONS: HOW?

The hydraulic solutions of the Daikin Group support Environmental Vision 2050, incorporating state-of-the-art energy-saving technology to help industries reduce energy consumption and produce fewer emissions.

More energy-efficient products

More energy-efficient products

- Development and adoption of refrigerants with low global warming potential

- Promotion of heat pump technology

Use of energy to perform efficient activities

Use of energy to perform efficient activities

- Management of buildings with centralized systems for energy efficiency and renewable energy

- Provision of energy services throughout the value chain

Recovery and recycling of refrigerants

Recovery and recycling of refrigerants

Daikin contributes to this project by creating value for the comfort and health of people, the cities they live in, the places they work, and the environment they depend on.

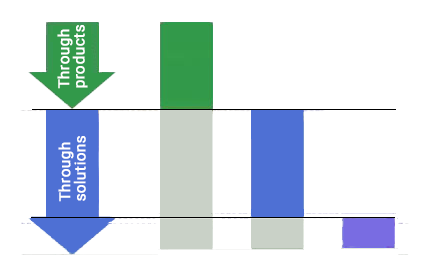

Energy consumption of a production line in a factory

45% of the total energy consumption in a factory comes from the machine line.

70% is a fixed energy consumption regardless of the production volume.

"WHAT A MATCH"

SUSTAINABLE INNOVATION

How does the application of inverter technology in hydraulics enhance the energy efficiency of your industrial machinery, improving sustainability and growth?

The combination of Duplomatic's extensive range of hydraulic equipment and engineering capabilities with Daikin's high-energy-saving technology will allow you to reduce your environmental impact in a wide variety of applications.

PRODUCTS FOR A SUSTAINABLE WORLD

Our products are designed with sustainability in mind.

From our cooling solutions to advanced technology in cylinders and electric actuators, we are committed to providing energy-efficient products that help reduce energy consumption and emissions.

Daikin Hybrid Hydraulic Systems: Technology Tailored to the Needs of Every Machine

Thanks to their versatility, Daikin hybrid hydraulic systems offer a complete range of functions and capabilities, ensuring a customized solution for every type of machine. In addition to this flexibility, the products stand out for low heat generation, a quiet operational noise level, and significant energy savings, contributing to optimizing operations in various facilities.

ECORICH: Innovation in Hybrid Energy Efficiency

-

Outstanding Energy Efficiency: The high-efficiency IPM motor surpasses the IE4 class, reducing energy consumption by 65% compared to conventional hydraulic units.

-

Optimal Thermal Control: Lowering oil temperature not only enhances the machine's thermal environment but also extends oil life, increasing intervals between oil changes.

-

Compact and Lightweight Design: The compactness and reduced weight simplify installation, with a 9% reduction in footprint across all models. The EHU1404/2504 model offers a 40% reduction in mass.

-

Compliance with CE Standards: All models adhere to high CE safety and quality standards."

SUPER UNIT: High Performance and Maximum Energy Savings

-

Superior Energy Efficiency: Thanks to the high-efficiency IPM motors with Daikin inverter technology, energy savings reach 50%, surpassing conventional hydraulic units altogether.

-

Multistage Pressure/Flow Control: The control panel of the SUPER UNIT allows for 16 different pressure (P) and flow (Q) settings, ensuring precise control of the cylinder for optimal operation.

-

Reduced Operating Noise Level: The dual-pump function enables the SUPER UNIT to maintain an operating noise level of only 60 dB(A) (at 206 bar pressure), dropping below 73 dB(A) in the operating area.

-

Compliance with CE Standards: All models strictly adhere to CE safety and quality standards.

AKZ - Oil Cooling Unit (Circulation Type)

-

High-Precision Temperature Control: Thanks to the use of Daikin inverter technology, temperature control achieves high levels of precision.

-

Superior Energy Performance: Unmatched energy efficiency is guaranteed, providing top-of-the-line energy-saving performance.

-

No Need for Transformer: The 400 V model is designed to operate without the need for an additional transformer.

-

Optimized Filter: Enhanced to minimize the risk of obstructions, the filter ensures continuous and reliable operation over time.

AKW - Water Cooling Unit (Circulation Type)

- High-Precision Temperature Control: Thanks to the use of Daikin inverter technology, temperature control is managed with high precision.

- Superior Energy Performance: Ensuring cutting-edge energy-saving performance, this series is synonymous with efficiency.

- No Need for Transformer: The 400 V model is designed to operate without requiring an additional transformer.

- Optimized Filter: Improved to minimize the risk of blockages, the filter ensures continuous and reliable operation over time.

en

en  it

it